Every truck driver knows the feeling of a dead battery on a cold morning. The road stretches ahead, and deadlines loom. Suddenly, your semi truck won’t start. Knowing how to use semi truck jumper cables is a lifesaver.

Professional drivers see truck battery cables as more than equipment. They are the key to getting back on the road quickly or facing delays. Heavy-duty jump starters are essential for reliable transportation.

Jump-starting a semi truck is different from a passenger vehicle. These machines need special knowledge, equipment, and care. This prevents damage to their electrical systems.

Key Takeaways

- Semi truck jumper cables must be 15-20 feet long with at least 2-gauge thickness

- Always wear protective gear when handling truck batteries

- Understand the unique 24-volt electrical system of semi trucks

- Charge batteries for at least five minutes before attempting to start

- Use heavy-duty cables designed for large commercial vehicles

Understanding Semi Truck Jumper Cables

Commercial vehicle jump packs are key for keeping diesel trucks running smoothly. They help semi-trucks deal with battery issues fast and well.

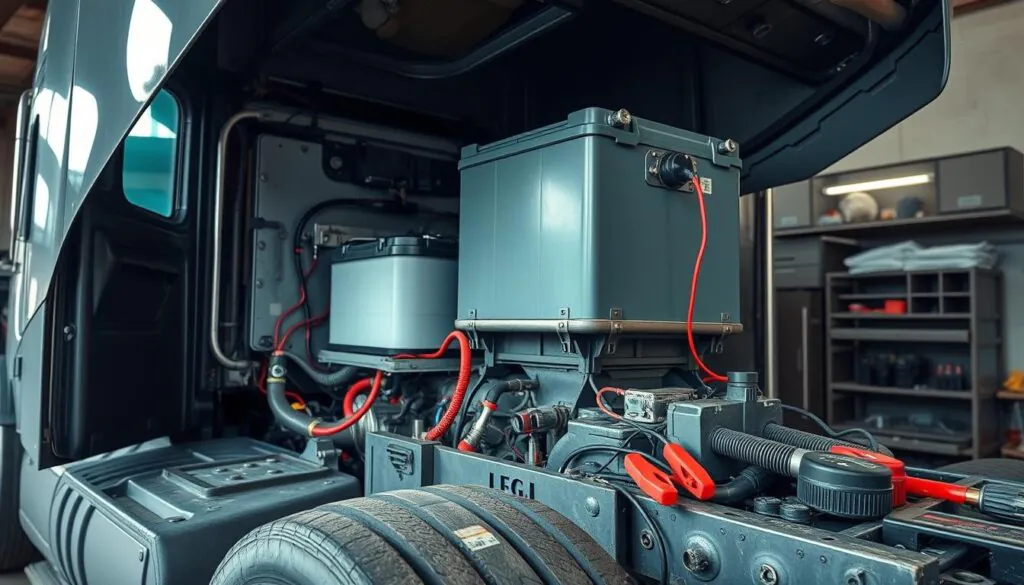

Semi-truck electrical systems are complex. They run on a 24-volt setup from two 12-volt batteries. So, diesel truck booster cables need to be strong enough for these needs.

What Are Semi Truck Jumper Cables?

Semi truck jumper cables are made for big commercial vehicles. They have special features that make them different from regular jumper cables:

- Extra-long cable length (20-25 feet)

- Thick gauge wire (0-4 gauge recommended)

- Heavy-duty insulated clamps

- Ability to handle high electrical currents

Key Features of Effective Jumper Cables

When picking diesel truck booster cables, experts look for certain qualities:

- Robust Conductivity: Can handle 24-volt systems

- Durability: Has thick, weather-resistant insulation

- Safety: Has insulated handles to avoid electrical shorts

Differences Between Light-Duty and Heavy-Duty Cables

Commercial vehicle jump packs stand out in important ways:

| Feature | Light-Duty Cables | Heavy-Duty Cables |

|---|---|---|

| Voltage Handling | 12 volts | 24 volts |

| Amp Capacity | Up to 500 amps | 5,000-10,000 amps |

| Recommended Use | Passenger Vehicles | Semi Trucks, Commercial Vehicles |

“Choosing the right jumper cables can mean the difference between a quick recovery and a costly breakdown.” – Professional Fleet Manager

Importance of Jumper Cables for Semi Trucks

Truck battery boosters are key for commercial vehicle operators. Long jumper cables can prevent a big problem from becoming a huge issue. Drivers know that battery failures can happen without warning, so being ready is a must.

Vehicle downtime can cost a lot. Truck operators face big risks when batteries fail unexpectedly. Having the right tools, like long jumper cables, can help avoid big financial losses.

Emergency Situations and Battery Failures

Battery failures can happen for many reasons:

- Extreme temperature conditions

- Extended periods of inactivity

- Age and wear of battery components

- Electrical system complications

Keeping Your Fleet Running Smoothly

Fleet managers know that prevention is key. Investing in quality truck battery boosters is a smart move to keep things running smoothly.

Reducing Downtime and Repair Costs

Preparedness is the key to minimizing unexpected operational interruptions.

Managing battery risks involves several steps:

- Carrying reliable long jumper cables

- Implementing regular battery maintenance

- Training drivers on proper jump-start procedures

- Maintaining backup power solutions

Being well-prepared can save trucking companies a lot of money. Jump start services for heavy-duty trucks can cost between $200 to $285. Having your own long jumper cables is a smart and affordable choice.

Choosing the Right Jumper Cables

Choosing the right jumper cables is key for truck drivers and fleet managers. The right big rig jump kits can mean the difference between a quick fix and a big problem.

Truck drivers know that not all jumper cables are the same. When picking cables for big trucks, several important factors need to be considered.

Gauge and Length Considerations

The cable gauge is very important for semi-truck electrical systems. Most drivers choose cables with a gauge between 0 and 4 for their strength. Key things to think about include:

- Thick copper cables (2/0 gauge) offer the best electrical flow

- Recommended cable length is 20 to 25 feet for easy use

- Lower gauge numbers mean thicker, stronger cables

Material and Durability Factors

Durability is key for tractor-trailer jump starters. Look for cables with:

- Heavy-duty insulation that can handle heat and oil

- Strong, well-insulated clamps

- Thick copper core for efficient electrical transfer

| Cable Gauge | Recommended Use | Typical Length |

|---|---|---|

| 0-4 Gauge | Heavy-Duty Semi Trucks | 20-25 Feet |

| 10 Gauge | Light Vehicles | 12-15 Feet |

Brand Recommendations for Quality Cables

Invest in professional-grade big rig jump kits from reputable manufacturers specializing in commercial vehicle equipment. While specific brand endorsements vary, focus on cables made for 24-volt systems with strong build.

“Not all jumper cables are created equal. For semi-trucks, quality is not an option—it’s a necessity.” – Professional Truck Fleet Manager

Preparing for Jump-Starting

When a semi-truck’s battery dies, being ready can save time and avoid danger. Knowing how to jump-start a truck safely is key. It involves careful planning and following safety rules.

Safety Precautions to Observe

When working with semi-truck emergency power, safety comes first. Drivers must take steps to protect themselves and their gear:

- Wear safety glasses to prevent eye injuries from battery corrosion

- Use latex gloves to shield against battery chemicals

- Stay away from open flames or sparks

- Check truck battery cables for damage before starting

Equipment Checklist Before Starting

Having a checklist for equipment can help drivers get ready for battery emergencies:

| Equipment | Purpose | Estimated Cost |

|---|---|---|

| Heavy-duty jumper cables | Primary jump-starting tool | $20-$25 |

| Portable battery pack | Alternative jump-starting method | $50-$75 |

| Safety glasses | Eye protection | $10-$15 |

| Latex gloves | Chemical protection | $5-$10 |

Assessing the Condition of Both Batteries

Before jump-starting, check the batteries’ condition. Look for corrosion, cracks, or leaks. Never jump-start a damaged or leaking battery.

Drivers say to wait about 2 minutes after connecting jumper cables before trying to start the truck.

By taking these steps, truck drivers can reduce risks and boost the chances of a successful jump-start. They can use their truck battery cables and emergency power supplies safely.

Step-by-Step Instructions for Jump-Starting a Semi Truck

Commercial vehicle jump packs are key for truckers with battery failures. Knowing how to jump-start a semi truck saves time and avoids delays.

Drivers know jump-starting needs focus and safety. Heavy-duty jump starters help with electrical issues on the road.

Positioning the Trucks Securely

Getting the trucks ready is the first step:

- Park trucks close but not touching

- Make sure both are on level ground

- Engage parking brakes for safety

- Turn off all electrical systems in both

Connecting the Jumper Cables Properly

Connecting cables right is key for a good jump-start:

- Use heavy-duty jump starters with 2-gauge cables

- Clean battery terminals for good contact

- Connect positive (+) cable to dead battery’s positive terminal

- Attach positive cable to good battery’s positive terminal

- Connect negative (-) cable to good battery’s negative terminal

- Attach negative cable to an unpainted metal ground on the engine block

Starting the Donor Truck: What to Do

Jump-starting a semi truck with commercial packs requires these steps:

| Step | Action | Duration |

|---|---|---|

| 1 | Start donor vehicle | 2-3 minutes |

| 2 | Let donor truck run | 10-15 minutes |

| 3 | Attempt to start semi truck | Up to 15 seconds per attempt |

“Safety and precision are key when jump-starting any commercial vehicle.” – Professional Trucking Safety Guide

Remember: Never crank the engine for more than 15 seconds to prevent starter damage.

Troubleshooting Common Issues

Diesel truck booster cables are key for fixing battery problems on the road. Truck drivers know that electrical issues can mess up their schedules.

Understanding common problems is vital for keeping vehicles running smoothly.

What to Do If the Engine Doesn’t Start

Engine start failures often come from a few main issues:

- Check starter motor functionality

- Inspect battery terminal connections

- Verify ground connections

- Test battery voltage levels

Signs of a Weak Battery

Commercial truck batteries show clear signs of weakness:

| Symptom | Potential Issue |

|---|---|

| Slow engine cranking | Low battery charge |

| Dimmed headlights | Insufficient power generation |

| Rotten egg smell | Battery acid leakage |

Avoiding Damage to Electrical Systems

To avoid electrical system damage, follow these steps:

- Never allow vehicles to touch during jump-starting

- Verify correct cable connection polarity

- Use high-quality diesel truck booster cables

- Consult professional mechanics for persistent issues

Electrical system failures can compromise critical truck operations and road safety.

Professional drivers know that regular maintenance stops expensive breakdowns and keeps transport reliable.

Proper Maintenance of Jumper Cables

Keeping long jumper cables for semi trucks in good shape is key. It ensures they work well when you need them most. Taking care of them also makes them last longer.

Cleaning and Storing Your Cables

Keeping your semi truck jumper cables clean stops corrosion and electrical problems. Here’s how to keep them in top shape:

- Wipe cables with a dry cloth after each use

- Remove any dirt or grease buildup

- Store in a cool, dry place away from direct sunlight

- Use a protective case to prevent damage

Regular Inspections for Wear and Tear

Regular checks can stop cables from failing when you need them most. Look for:

- Frayed or exposed wire strands

- Crack or damage in cable insulation

- Loose or corroded clamps

- Signs of metal deterioration

Signs It’s Time to Replace Them

Knowing when to replace your jumper cables is important for safety. Look out for these signs:

| Condition | Action Required |

|---|---|

| Visible copper wire exposure | Immediate replacement |

| Significant insulation damage | Replace cables |

| Corroded or loose clamps | Consider replacement |

“A well-maintained set of jumper cables can be the difference between a quick recovery and a costly breakdown.” – Professional Truck Maintenance Expert

Pro tip: Always keep a spare set of high-quality semi truck jumper cables in your vehicle for unexpected emergencies.

Safety Tips During the Jump-Starting Process

Jump-starting a semi-truck needs careful safety steps. Tractor-trailer jump starters require precision to avoid electrical dangers. Drivers must know the key safety steps to protect themselves and the truck.

When using heavy-duty jump starters, safety is top priority. Here are some tips to reduce risks during jump-starting.

Wearing Safety Gear

Wearing the right safety gear is key when working with semi-truck electrical systems. Drivers should always wear:

- Safety glasses to protect eyes from battery acid splashes

- Insulated work gloves to prevent electrical shock

- Long-sleeve protective clothing

- Non-conductive footwear

Avoiding Sparks and Short Circuits

To avoid electrical accidents, manage cables carefully for tractor-trailer jump starters. Follow these important steps:

- Ensure cable clamps never touch each other

- Check battery terminals for corrosion before connecting

- Connect cables in the correct sequence

- Avoid touching metal surfaces during connection

Keeping Clear of Moving Parts

When jump-starting heavy-duty jump starters, stay away from engine parts. Keep loose clothing, jewelry, and long hair tied back to avoid getting caught in moving parts.

*Safety is not an accident. It’s a choice.* – Unknown

| Safety Measure | Recommended Action |

|---|---|

| Battery Inspection | Check for cracks, leaks, or damage before jump-starting |

| Electrical Disconnect | Turn off all electrical systems before connecting cables |

| Cable Connection | Use proper sequence: positive to positive, negative to ground |

By following these safety tips, drivers can lower risks when jump-starting semi-trucks. This protects them and their valuable equipment.

Final Steps After Jump-Starting

Jump-starting a semi-truck needs careful steps at the end. Drivers know that the right actions after starting are key. They help keep the truck’s electrical system working well and avoid battery problems later.

After using big rig jump kits to start your truck, you must follow important steps. These steps keep your truck’s electrical system healthy.

Disconnecting the Cables Correctly

Removing jumper cables needs care to avoid damage. Here’s how to do it right:

- Remove positive cables first from both batteries

- Disconnect negative cables starting from the grounded vehicle

- Ensure cable ends do not touch during removal

Running the Engine to Recharge

After jump-starting, let the semi-truck’s engine run for about 20 minutes. This lets the emergency power supplies recharge the battery. It makes sure the battery has enough power for future starts.

*Pro Tip: A fully charged semi-truck battery typically maintains around 24 volts of power.*

Monitoring the Battery’s Performance

Keep a close eye on your battery’s health after jump-starting. Look out for signs like:

- Slow engine cranking

- Dimming dashboard lights

- Frequent need for additional jump-starts

If you see these signs often, get a mechanic to check your battery or electrical system.

Alternative Solutions to Battery Issues

Truck drivers and fleet managers face unique challenges with battery problems. Commercial vehicle jump packs and diesel truck booster cables offer new solutions. These go beyond traditional jump-starting methods.

Dealing with battery issues needs a wide range of solutions. Modern trucking professionals have many options to keep their vehicles running well.

Portable Jump Starters for Semi Trucks

Portable jump packs are key tools for commercial vehicle operators. They provide critical backup when traditional jump-starting isn’t possible.

- High-capacity jump packs with 1500+ Cold Cranking Amps (CCA)

- Compact designs for easy storage in commercial vehicles

- Quick charging capabilities for diesel truck booster cables

Battery Maintenance Tools

Preventive maintenance can stop unexpected battery failures. Smart chargers and diagnostic tools protect semi-truck electrical systems.

| Tool Type | Key Benefits | Average Cost |

|---|---|---|

| Smart Battery Charger | Controlled charging, battery health monitoring | $100-$250 |

| Voltage Meter | Real-time battery performance tracking | $50-$150 |

| Battery Load Tester | Comprehensive battery condition assessment | $75-$200 |

Consulting with a Professional Mechanic

When other solutions don’t work, getting help from a professional is key. Certified mechanics can find complex electrical issues that simple tools miss.

Professional diagnosis can save thousands in repair costs and prevent breakdowns.

Modern commercial vehicle jump packs are a big step forward in managing battery issues on the road. Investing in quality tools and getting professional advice ensures your vehicle runs smoothly and saves on downtime.

Summary and Best Practices

Managing truck battery cables well is key to avoiding unexpected failures. Semi truck jumper cables are essential for drivers, ensuring they can handle emergencies safely. Knowing how to maintain batteries can cut down on downtime and repair costs in the trucking world.

Drivers should be ready by getting top-notch semi truck jumper cables and checking their electrical systems. Tools like the SOLAR BA327 digital battery tester can spot issues early. It tests batteries from 40-2000 CCA and finds problems with charging systems.

When working with truck battery cables, safety is the top priority. Drivers need to know how to connect cables right, understand battery grounds, and use the right jump starters. Lithium jump starters are great for their size and power, making them a top choice for truckers.

Regular checks, proactive care, and keeping up with battery tech are vital. These steps help truckers avoid risks and keep their vehicles running well. By following these tips, drivers can keep their trucks running smoothly and safely, no matter where they go.